Conventional System

Concrete is one of the most used materials for the execution of structures in civil construction, mainly due to the easy obtaining of its raw material and the high durability of the product. To guarantee this characteristic, some factors are of paramount importance, among them the covering of the iron armor.

When we talk about covering iron reinforcement, we are referring to the thickness of concrete existing between the outer edge of the steel and the inner face of the formwork. This thickness is intended to protect the steel from environmental agents that can cause corrosion and from physical shocks that can damage the structure, among other functions. The lack of attention to this fundamental procedure can result in structural recovery rework, and this almost always involves high costs for builders and developers.

The Brazilian standard ABNT NBR 6118:2014, equivalent to the international standard ISO 19338, determines the minimum thickness of this covering, in addition to its characteristics and dimensions established in the projects. In the past, the solution found by the works was the manufacture of spacers made with mortar, but it was an unsatisfactory solution since these spacers proved to be brittle, permeable, with a high rate of loss, low production, and difficult handling and storage over time. In other words, they were products with little reliability and that more complicated the work than they helped.

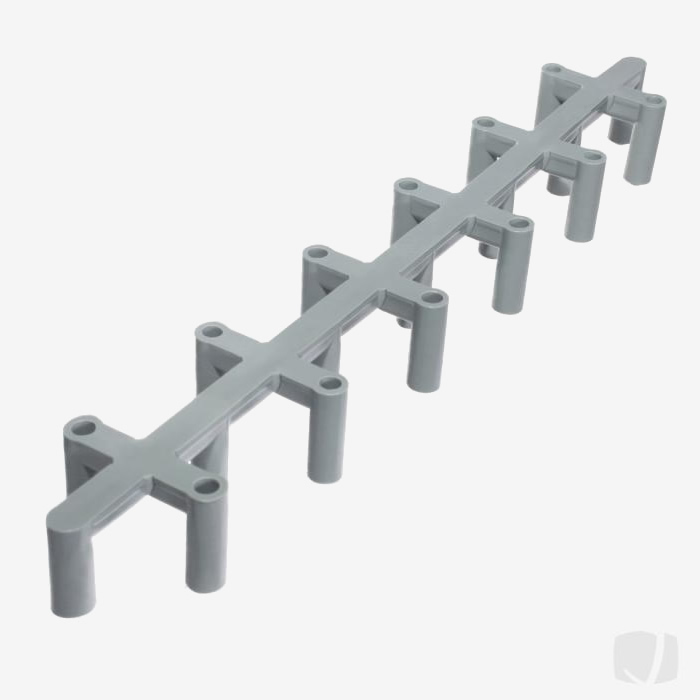

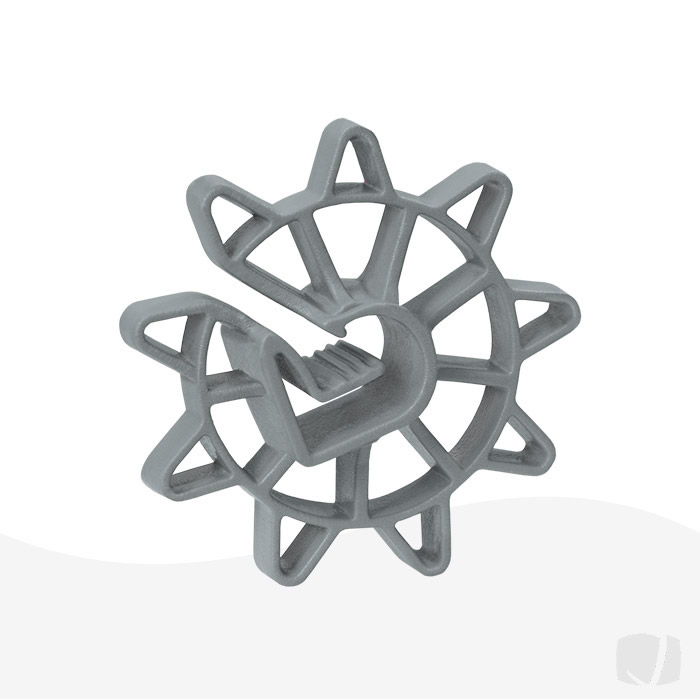

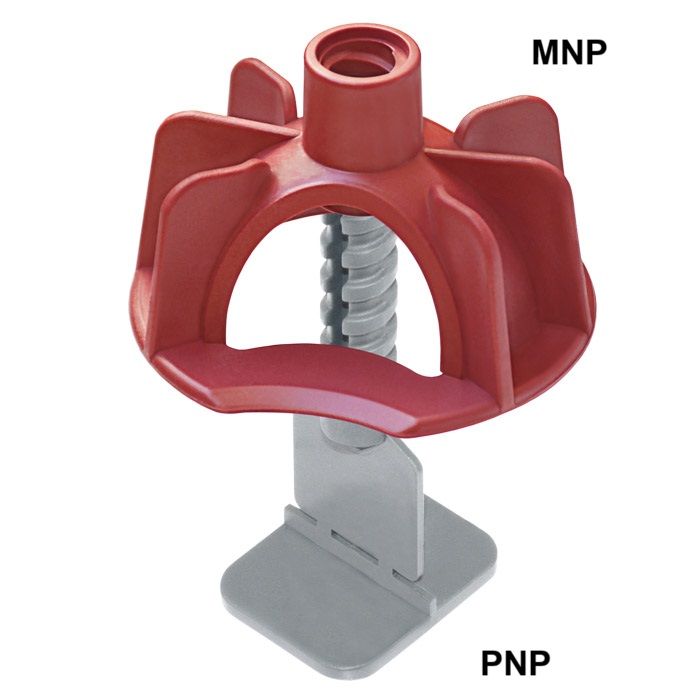

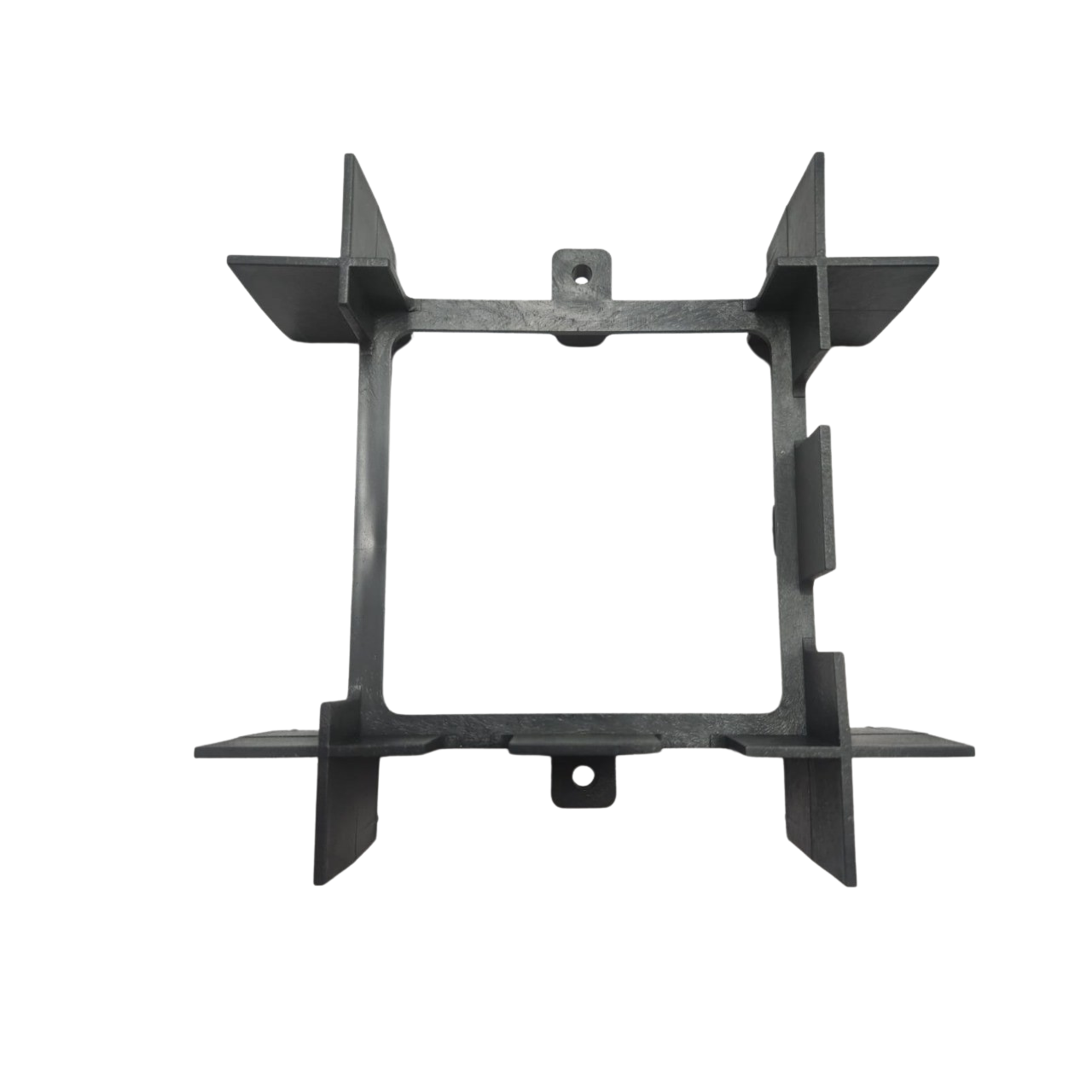

Thinking about bringing a true and modern solution, Jeruel Plásticos invested in the manufacture of a complete line of plastic spacers that suit the needs of any production and work. Our models have a competent designer, with anti-opening fittings and locks with good adhesion to concrete and easy to use.

Consumption varies and adapts to each case, taking into account the efforts to which the spacer will be subjected at the time of concreting (weight of iron, workers and energy released by the consolidation equipment).